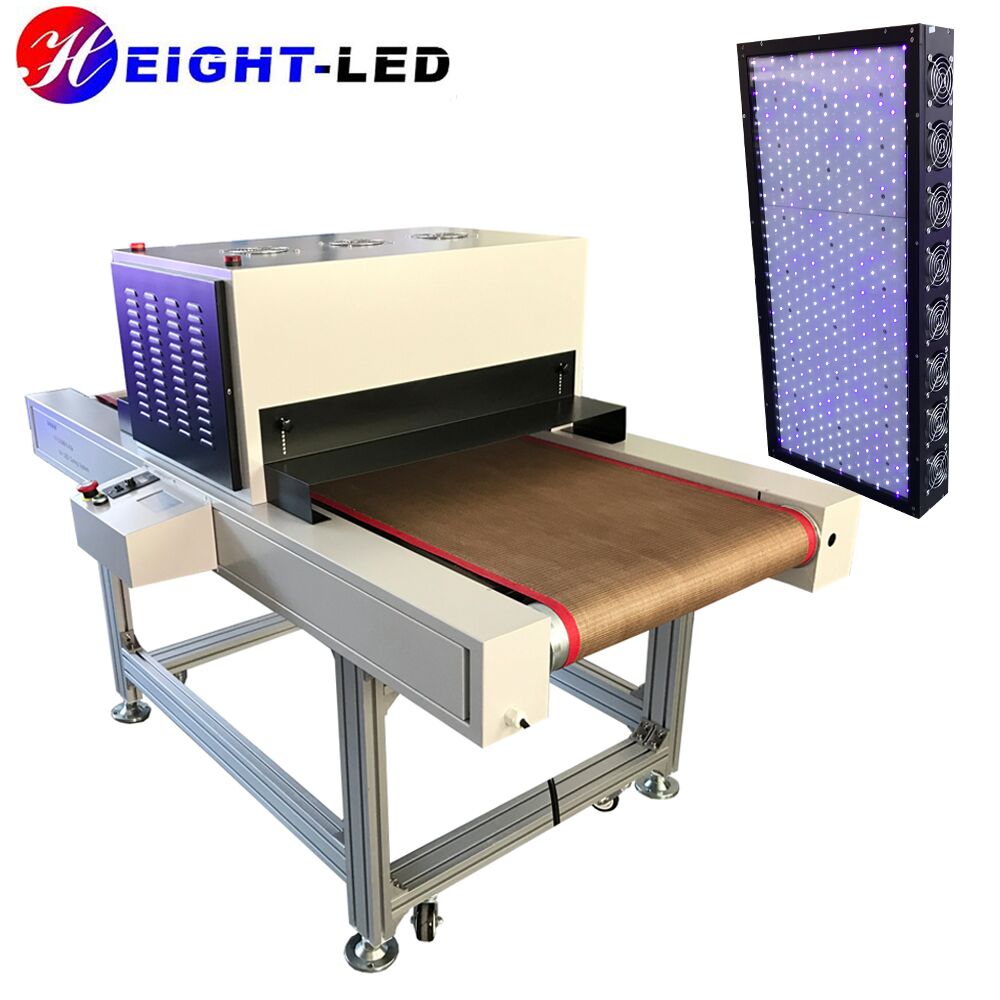

In recent years, LED UV curing technology has received widespread attention in the electronics, medical, optical and

other industries. The application of LED UV curing machine is also very extensive. UVLED is an electroluminescent diode.

Compared with traditional UV mercury lamps, it is more environmentally friendly, efficient and has low energy consumption.

It is a green industrial technology that can truly face sustainable development. Many manufacturers have also put LED UV

curing machines into production and enjoy the efficiency and convenience brought by LED UV. After purchasing the LED UV

curing machine, what problems should be paid attention to when using it?

1. Security

(1)Before starting the machine, check whether the body has good grounding protection.

(2)When the machine is running, it is strictly forbidden to reach into the machine to avoid unnecessary accidents.

(3)Skin or eyes cannot be exposed to ultraviolet light for a long time to avoid burns.

(4)In case of abnormal power failure at any part, the main power supply should be turned off, and then the machine should

be turned on after troubleshooting.

2. maintenance problems

(1)When using the LED UV curing machine, check all parts of the body in advance. If abnormal conditions are found, please

contact the maintenance personnel to repair. Wait to make sure that the device is normal before starting.

(2)Please clean the LED UV curing machine in time before and after use. When cleaning, remember not to rinse with water,

and remember not to rinse with water, especially the LED UV light window and heat dissipation opening. If the glass of the

light exit window is not cleaned for a long time, it will affect the penetration of the LED UV light, resulting in incomplete

curing of the glue or ink; the heat dissipation refers to the air outlet and air inlet, and also includes the water-cooled LED

UV curing machine. Inside, if the air inlet is not cleaned for a long time, it will be blocked by dust or foreign objects, resulting

in poor heat dissipation. For the same reason, the air outlet should not be blocked.

(3)Maintain the components of the LED UV curing machine regularly, and measure the radiant power of the LED UV curing

machine regularly every month or quarter to see if there is any attenuation or loss, and deal with the broken uvled lamp

beads in time. The water-cooled LED UV curing machine needs to focus on checking whether the internal circulating water

has more impurities, and it is very necessary to regularly replace the circulating water.

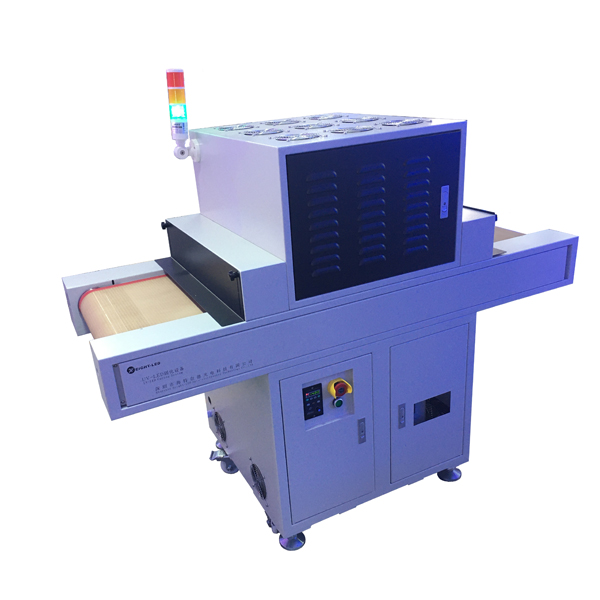

LED UV curing machine has a wide range of applications. When using it, please pay attention to safety issues and protect

yourself. Also pay attention to the maintenance of LED UV curing machine, because timely maintenance can ensure the good

condition of the equipment and not affect its service life and working efficiency.